PRODUCTS

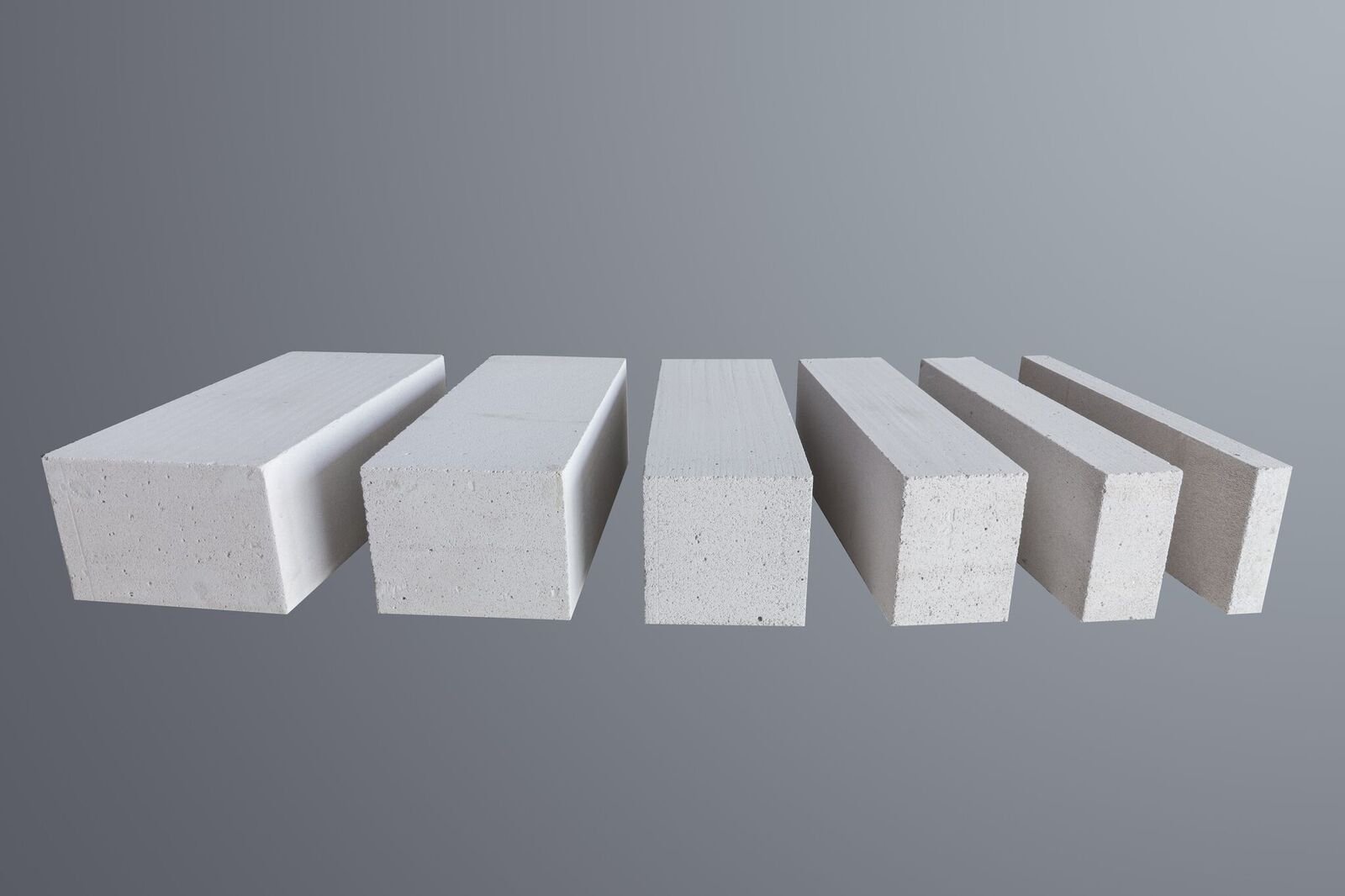

AAC Blocks

AAC Blocks are manufactured from Autoclave Aerated Concrete (AAC). This is made from lime, sand and Cement, to which a frothing agent Aluminum powder is added to aerate the Concrete. The partially cured concrete is then autoclave to complete the curing and to promote the formation of a crystalline structure. The aeration and low density (Approximately one quarter of the density of standard Reinforced concrete) enables blocks to be easily cut, drilled and shaped by hand. Blocks are glued together to form solid Masonry structural walls with excellent thermal and acoustic Properties.

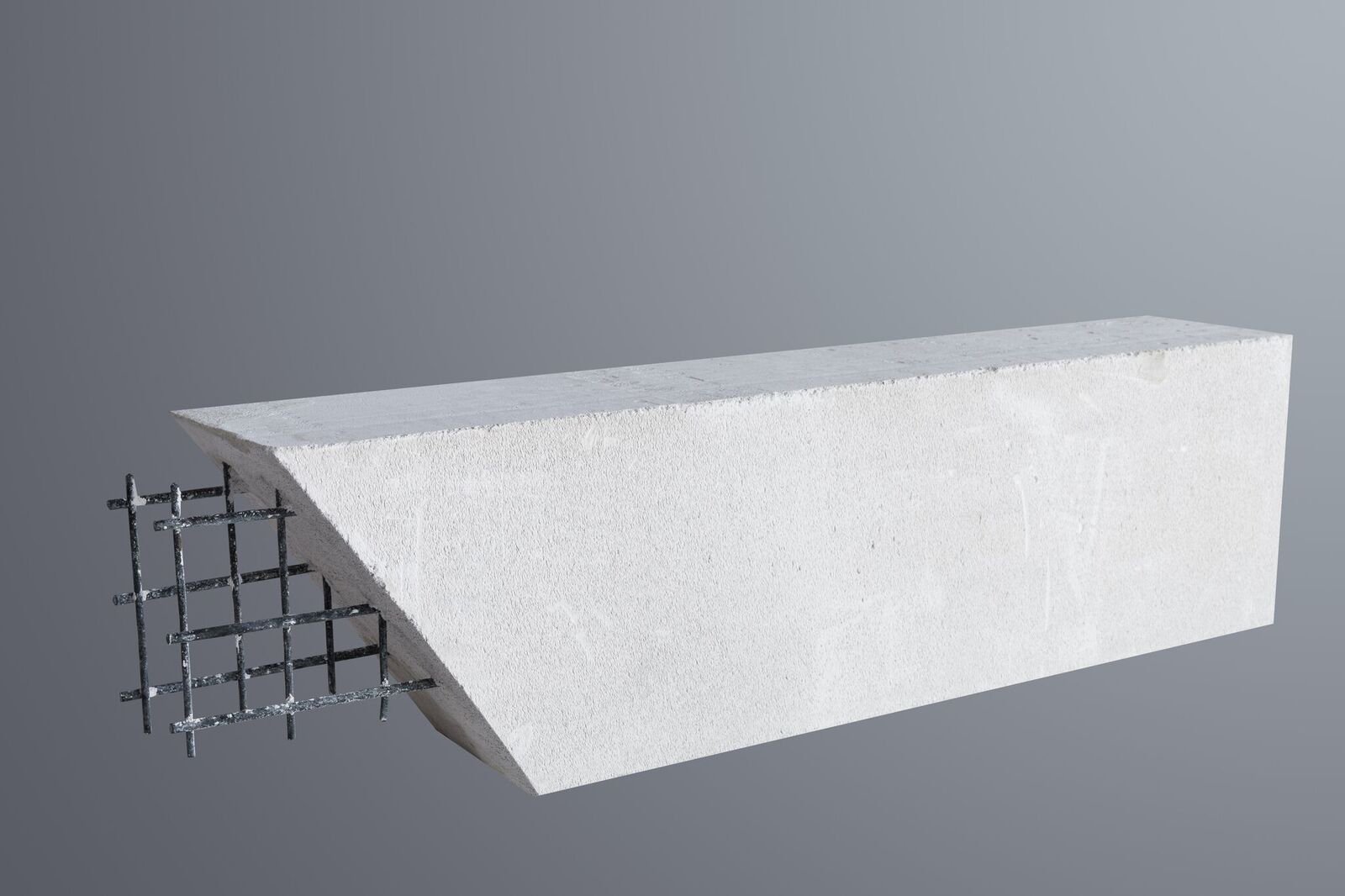

AAC Lintels

AAC steel reinforced lintels are supplementary components used in conjunction with the blocks and are widely used over portals, doors and windows. It has been proven that using AAC lintels can accelerate the construction time and reduce the labor cost compared with traditional methods. Composed of the same raw material as AAC Blocks, AAC Lintels ensures the wall is solid and free from material incompatibility with AAC Block and avoids thermal bridging combined with a uniform substrate for rendering. The size of AAC lintels can be customized in line with the opening and wall thickness up to a maximum clear span of 3000mm. The reinforcement rebar is the key factor of the AAC lintel and guarantees the correct load bearing capacity. Various types of lintels are available depending on the purpose.

AAC Panels

Precast Aerated Concrete AAC Panels are lightweight, fire resistant, fast and easy to install. AAC panel is a reinforced (Grade 70 steel) element spanning with full story height.AAC Panel is based on a standard 60 cm wide module. The thickness and panel length (height) vary depending on the design requirements and constraints of the project. AAC Panels can be applied vertically or horizontally according to the application. It is produced with a groove from both sides (thickness sides) where grout is poured in case of load bearing wall system. It also comes plain on edges when it is applied as partition walls, boundary walls, shaft walls, cladding on steel structure or concrete structure. In this case, fixation will be through using thin bed mortar AAC Adhesive and steel angles.

AAC Slabs

AAC Floor and Roof Slabs are lightweight, fire resistant, fast and easy to install and provide lifelong superior thermal insulation. AAC Slabs are steel reinforced (Grade 70) Autoclaved Aerated Concrete elements. The interior steel wire reinforcement is covered with an anti-corrosion coating. AAC Slab Panel is produced in an ASTM C 1452 strength class: AAC-6. PAC Slabs are produced with 20 cm or 25 cm thickness with a maximum span of 6 meters. In case of longer spans more than 6 meters, a steel beam will be added as a support for the slabs which can be inserted inside the beam. With 20 cm slab thickness, IPE 220 beam is used and in case of 25 cm thickness, IPE 270 beam is used. PAC slabs has a special profile groove of 5 cm on top edge where a steel rebar 12 mm is inserted between the slabs and grouted with none shrinkage grout. In these case, structural screed of 5 cm on top will not be needed.

AAC Mini Panel

Mini panel is a non-reinforced panel system which gives more economical solution than the reinforced panel system. Mini panel system is composed of: High density load bearing non reinforced panels. Reinforced AAC lintels for walls (above doors and windows openings) and Reinforced AAC Slabs for roof. It is a load bearing wall system where no columns are needed except in very rare cases for the staircase or as a support for some steel beams.

AAC Adhesive

A high performance adhesive for AAC Blocks. A cement based Adhesive; Easy to apply.